The booming development of the modern farming industry has also brought a lot of thorny problems for farmers, such as the treatment of livestock and poultry manure. As we all know, livestock and poultry manure is a very valuable natural resource. If handled properly, it can bring farmers a considerable amount of income without burdening the environment. If not handled properly, it will not only pollute the environment, but also have a great impact on the environment of the farm and the health of livestock and poultry. In this paper, we will analyze and discuss how to deal with livestock and poultry manure so as to realize the environmental protection and benefit win-win departure.

1. Common treatment methods of livestock and poultry manure

①Drying method

Many farmers will use manure drying method. Through the drying process, the water content of livestock and poultry manure is greatly reduced at the same time, the volume of manure will also be reduced, easier to transport and storage. The dried manure can be used as a fertilizer on farmland. However, the drying process cannot completely remove the pathogens and pest eggs in the manure, and it may pollute the environment or spread bacteria after being used as fertilizer.

②Anaerobic consumption method

Anaerobic depletion is also used by some farmers. By creating an anaerobic environment, anaerobic microorganisms are promoted to multiply and decompose organic matter. After the decomposition process is completed, biogas and digestate will be produced. Biogas is commonly known as methane, which is a clean energy source that can be used to generate electricity and heat. The digestate can be used as a fertilizer and put back into the farmland. This treatment method has high cost and high technical requirements, so it is not suitable for promoting the use in small farms.

③Aerobic fermentation

Aerobic fermentation is also a method often used by farmers. Aerobic fermentation is to control the environment with suitable temperature, humidity and oxygen content to promote the decomposition of organic matter by aerobic microorganisms. Aerobic fermentation is mainly done by traditional composting and fermentation in revolutionary commercial composting machines. Conventional composting produces fertilizers that may carry pathogens and pest eggs, and will have an odor that will pollute the soil and atmosphere. Next, I will give you a detailed introduction to the advantages of organic waste commercial composting machine fermentation in terms of both environmental protection and profitability.

2. Advantages of best selling industrial composting machine fermentation in terms of environmental protection and profitability

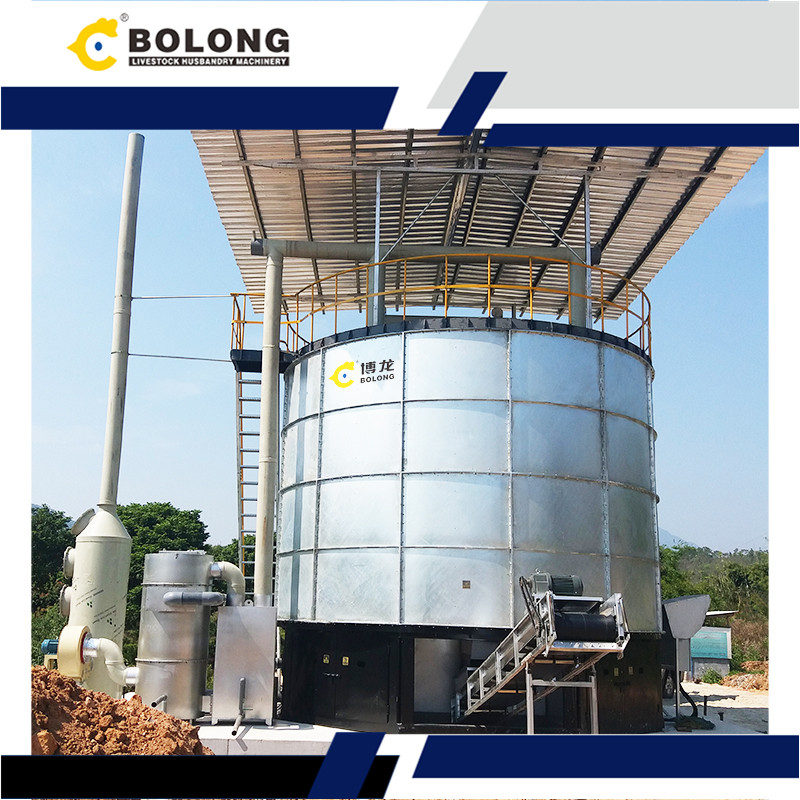

Environmental benefits: The environmental friendliness of optimized space utilization industrial composting machine fermentation is relatively high. First, odor control, the composting machine is a closed tank, which largely reduces the leakage of gases produced during the fermentation process into the atmosphere. Secondly, many composting machine manufacturers will equip the advanced technology commercial composting machine with a special deodorization system, which will further purify the gas produced after fermentation and discharge it into the atmosphere after meeting the emission standards. On the other hand, pathogens and pest eggs within the fertilizer fermented in the composting machine will be removed during the fermentation process, preventing contamination of the soil after use as fertilizer.

Increase revenue: The global sales commercial composting machine requires less manpower to operate, and can realize the operation mode of one person with multiple stations, which reduces the operation cost to a large extent. Some manufacturers, such as Bolong, have designed and developed odorless commercial composting machines that do not require the addition of auxiliary materials for the fermentation process to run smoothly, which reduces raw material costs to a certain extent. In addition, the composting machine fermentation method can be used to convert livestock and poultry waste into fertilizer, which is a considerable income after sale.

3. Notes on the use of economical and energy-efficient industrial composting machine

①Regular cleaning and sterilization of equipment

When using the integrated design poultry composting machine, you need to clean and disinfect the equipment regularly. This can avoid cross-infection, ensure the cleanliness of the fertilizer, and improve the quality of organic fertilizer.

② Precise adjustment of fermentation conditions

The fermentation process should be clear that the appropriate fermentation temperature, humidity, oxygen content and other indicators, timely adjustment of the variety of sizes commercial composting machine indicators to ensure that the fermentation effect.

③Regular maintenance of equipment

The use of easy operated commercial composting machines in the process of regular inspection and maintenance of equipment. Problems with the global leadership industrial composting machine are repaired in a timely manner to avoid potential safety hazards and ensure the safety of workers.

If you want to achieve a win-win situation in the process of livestock and poultry manure treatment, I would recommend that you choose the right organic fertilizer professional engineering team customized composting machine, which can bring you a considerable income at the same time as environmental protection. If you have any questions or want to know in the process of purchasing high degree of automation industrial composting machine, please feel free to contact us, we have a professional technical team and service team ready to serve you!