At present, the world is comprehensively advancing the rural revitalization strategy, the development of agricultural circular economy has been fruitful, and the scale of livestock and poultry breeding continues to expand, but the problem of odor has become prominent. With the current tightening of environmental protection policies and stricter emission and monitoring standards, odor problems still restrict the development of many industries. The treatment of waste gas from livestock and poultry breeding is urgent. Solving the problem of odor from livestock and poultry breeding is related to the construction of ecological civilization. Relatively speaking, deodorization at the end of the composting machine is the most effective part of the entire deodorization process. This article will start from the deodorization technology at the end of the composting machine, analyze the deodorization technology of the long life composting machine and introduce the latest deodorization technology of Bolong.

1. Composting machine terminal deodorization technology

The common treatment methods currently on the market for deodorization at the end of composting machines include the following:

①Physical deodorization method of composting machine

The principle of the long life composting machine physical deodorization method is to rely on activated carbon to absorb the odor generated by the composting machine. It has the advantages of convenient operation and quick results, but it is only suitable for low concentration and low range odor treatment. This method is mainly based on physical processes, but its shortcomings are incomplete deodorization, high treatment costs, and improper treatment that can easily cause secondary pollution.

②Chemical deodorization method for composting machines

The chemical deodorization method of global sales composting machines mainly includes the acid-base absorption method, which collects the waste gas generated by the global sales composting machine, sprays acid detergent or alkali detergent to the waste gas according to the type of waste gas, and conducts a chemical reaction after the waste gas and the detergent come into contact. Thereby achieving the purification effect of exhaust gas. The composting machine chemical deodorization method has a mature process and has the advantages of high efficiency, thorough deodorization, safety and reliability. The disadvantages are high operating costs, large energy consumption, complex processes, etc. It is mainly used for high-concentration industrial odor treatment.

③ composting machine biological deodorization method

The principle of the space saving composting machine biological deodorization method is that the gas components first come into contact with water and dissolve in the water, and then are captured and absorbed by the microorganisms in it; the odor components entering the microorganisms are decomposed as energy and nutrients during their own metabolism, eventually converted into harmless compounds through biochemical reactions.

Each of the three space saving composting machine terminal deodorization technologies has its advantages and disadvantages, and the disadvantages of a single technology are obvious in the application process. In order to completely solve the odor problem, Bolong specially upgraded the deodorization system and combined a variety of deodorization technologies. Next, I will introduce to you in detail Bolong’s newly upgraded easy operated composting machine deodorization system.

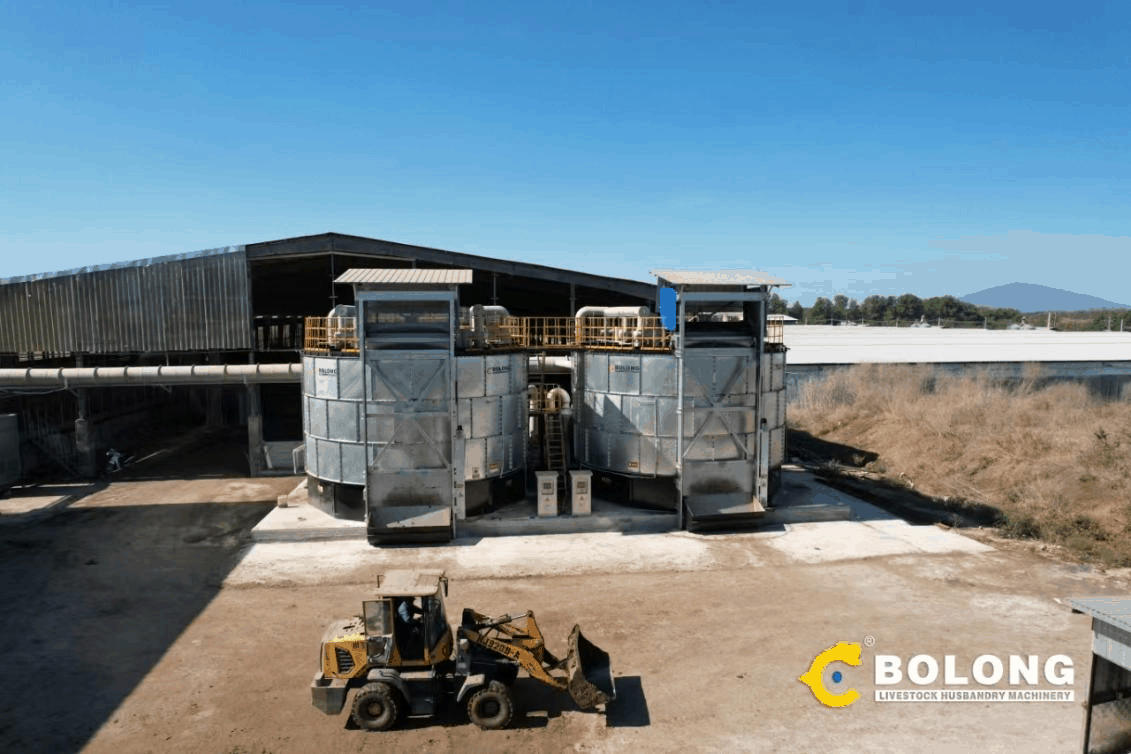

2. Bolong’s newly upgraded easy operated composting machine deodorization technology

Bolong deodorization system 5.0 uses activated carbon adsorption method combined with microbial decomposition technology and water spray technology to cleverly comprehensively control waste gas. The odor generated by the safe and reliable composting machine is sent to the spray tower through the air inlet pipe, and the water containing a large number of microorganisms in the storage tank enters the spray tower through the water inlet pipe to form a water curtain. Some of the sulfides, ammonia nitrogen and other components in the exhaust gas are absorbed or dissolved by the liquid film on the surface of the biofilm in the water curtain, and are eventually degraded into CO2, H2O, inorganic salts and other substances. After preliminary treatment, the waste gas will enter the activated carbon adsorption layer. The waste gas flows through the activated carbon layer from bottom to top. The small amounts of sulfide, ammonia nitrogen and other components remaining in the waste gas are finally captured by the activated carbon. The entire system has a remarkable deodorizing effect, and the subsequent operation and maintenance is relatively simple.

Bolong’s newly upgraded 5.0 deodorization system uses activated carbon adsorption method combined with microbial decomposition technology and water spray technology. Compared with the common composting machine end deodorization systems that only use physical or biological methods on the market, Bolong deodorization system 5.0 perfectly overcomes the shortcomings of incomplete physical treatment and unstable biological deodorization effect, achieving high environmental friendliness while ensuring deodorization effect. Realize intelligent energy saving and remote monitoring, effectively reduce composting machine operation and maintenance costs and improve operation and maintenance efficiency.

With the rapid development of animal husbandry, the resulting breeding pollution problems have become increasingly prominent, and the constraints on the development of animal husbandry have become more and more prominent. Strengthening the prevention and control of breeding pollution, especially odor reduction and control, has become a sustainable development goal for the animal husbandry industry at this stage. development priority. When purchasing high quality composting machines, we should also choose equipment with good deodorization effects. If you have any questions about high quality composting machines, please feel free to contact us. We have a professional technical team ready to serve you!