-

advanced technology Livestock and husbandry manure compost tank

Livestock and husbandry manure compost tank Organic waste such as poultry manure and animal carcasses such as chicken, pig, cow and sheep manure can be processed and turned into usable organic fertilizer 133-2392-6737 Online service Advantages and characteristics A design and development team that strives for perfection Tank closed

Get Price -

The Future of Livestock Fermentation Tanks

This article explores future trends and developments in the field of fermentation tanks for livestock manure management. Technological Advancements: Continuous improvements in technology will enhance the efficiency, automation, and environmental performance of fermentation tanks.

Get Price -

Aerobic Compost Fermentation Tank for Cow Manure Compost

1. Q: What fields is the high temperature aerobic fermentation tank mainly used in? A: The high temperature aerobic fermentation tank can be used for Livestock and poultry manure (pig manure/chicken manure/cow manure) composting, organic waste (straw and garden waste) recycling, municipal sludge, kitchen waste and fruit and vegetable waste. 2.

Get Price -

advanced technology manure composting equipment

May 10, 2022 · The suitable C/N in the process of cattle manure composting is 20-30:1 (30:1 is ideal). Ventilation: The major function of ventilation is to provide the necessary oxygen for aerobic microorganism growth and breeding, remove the redundant water content in the stockpile, adjust the temperature and reduce foul smell via controlling air demand.

Get Price -

Microbiological and Technological Insights on Anaerobic

May 2, 2023 · Anaerobic digestion of animal manure results in the production of renewable energy (biogas) and nutrient-rich biofertilizer. A further benefit of the technology is decreased greenhouse gas emissions that otherwise occur during manure storage. Since animal manure makes anaerobic digestion cost-efficient and further advance the technology for higher methane yields, it is of utmost importance to

Get Price -

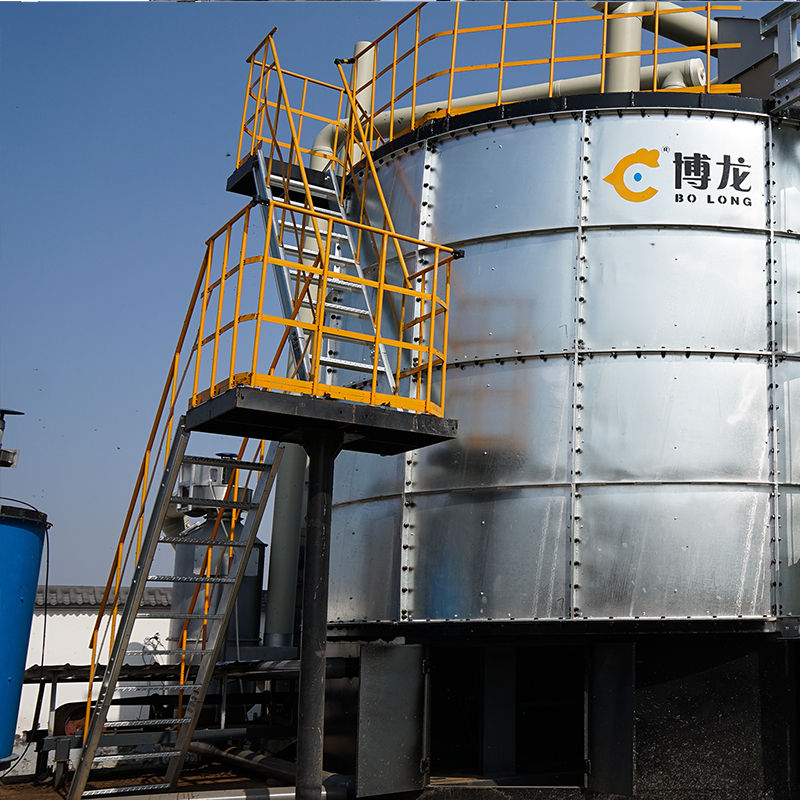

Aerobic Fermentation Tank - Manure Fermenter and Manure

Function: Economic High Efficeint Poultry Manure Treatment Aerobic Fermentation Tank is a new generation of organic fertilizer fermentation tank which is suitable for different regions, based on the similar equipment and through improvement and upgrading. Advanced technology level, leading technology in the country, favored by the majority of

Get Price -

China Top Fertilizer Fermentation Tank Manufacturer

The fermentation time of the fertilizer fermenters is relatively short. In the traditional method, it takes about 20 days to compost organic matter with a turner. However, if you use a Bolong fermentation tank to compost organic matter, the first fermentation process will last about 7 days, with subsequent daily drop-offs and outputs continuing.

Get Price -

Aerobic Fermentation Tank In tank Tank Fermentation Machine

Scope of Application High Temprature High Pressure Chicken Manure Fermentation Tank /In tank Compost Turner/Chicken Dung Fermentation Tank 1. Livestock and poultry manure: chicken manure, cow, sheep, horse manure, rabbit manure, etc. 2. Agricultural waste: such as straw, soybean meal, cotton meal, etc. 3.

Get Price -

A Two-Stage Anaerobic Digester of Pig Manure and Food Waste

manure and food waste was built according to the schematic diagram shown in Fig. 1. The digester consisted of a 150 L-acid tank and a 250 L- gas fermentation tank. Both tanks were made of cylindrical polyvinylchloride (PVC). The acid tank and fermentation tank were connected to a biogas collection tank via an airtight PVC tube.

Get Price -

Innovations in Livestock Fermentation Tank Design

Case Study: A large poultry farm adopted fermentation tanks with the latest design innovations. The advanced aeration and temperature control systems improved the efficiency of manure processing, while the odor control system minimized environmental impact. The farm achieved better manure management and enhanced sustainability.

Get Price -

Straw Manure Aerobic Fermentation Tank for Organic Compost

1. Q: What fields is the high temperature aerobic fermentation tank mainly used in? A: The high temperature aerobic fermentation tank can be used for Livestock and poultry manure (pig manure/chicken manure/cow manure) composting, organic waste (straw and garden waste) recycling, municipal sludge, kitchen waste and fruit and vegetable waste. 2.

Get Price -

An Advanced Biogas Plant for Bio-Circular Economy from Pig

The advanced biogas technology of a two-stage high-efficiency anaerobic fermentation technology for wastewater system in “Xin He Xing” pig farm was then first realized in Taiwan. Nearly 80% of pig farms are operated on a small-scale mode in Taiwan. Generally, small farmers cannot invest in large

Get Price -

Development and Evaluation of Cow Dung Composting Equipment

Jul 27, 2023 · Traditional cow manure composting equipment often lacks ventilation, heating, and real-time monitoring and adjustment capabilities, hindering manure maturation and proper utilization of compost, moisture reduction, and optimal environmental conditions for microbial activity. To address these limitations, we optimized and redesigned the structure and control elements of conventional composting

Get Price -

The Future of Livestock Manure Management with Fermentation Tanks

Advanced Technology: Fermentation tanks incorporate cutting-edge technology to enhance the efficiency and effectiveness of manure management. Advanced aeration systems, automated monitoring and control, and odor and emission control are key features that set these tanks apart.

Get Price -

advanced technology Urban sludge compost tank

processes and technologies dewatered sludge treatment sludge composting principle and conditions governing its use principle and conditions governing its use Reading time: 20 minutes Composting is controlled fermentation that converts organic matter aerobically and produces stable humic and pre-humic compounds (figure 1).

Get Price